Nose3D: Segmentation and additive manufacturing of nasal sinuses for an ENT testbed.

The Medical Problem

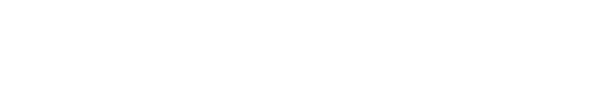

Chronic sinusitis is the most common chronic disease in the western world. In generally nasal disorders are among the most common health problems. In many cases the high degree of pain results in surgeries without the desired results. This motivates research in this important ENT (ear-nose-troath) topic. The bone structure of the nasal region including nasal cavity, auxillary, frontal, ethmoid and sphenoid sinuses is the most complex one in the human body. Therefor special techniques for visualization and segmentation of image data are needed.

Project NOSE-3D

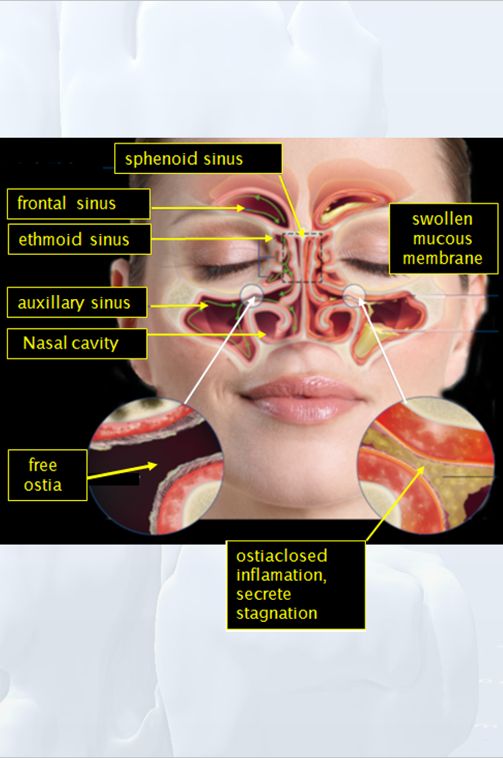

The project aims at developing a physical device, the "NOSE Air Flow Simulator", for displaying and measuring air flows in nasal cavities. The research goal is to validate the computer simulations, 3D meshes and computational fluid dynamics (CFD) within the nasal cavities, against an in vitro model. For that purpose a new method of high quality true-to-life 3D printing of the nasal cavities will be developed. STL-data from artificial intelligence (AI) supported segmentation are used for 3D-presentation, CFD as well as 3D-printing of individual physical models.

Segmentation (AIT– Graz)

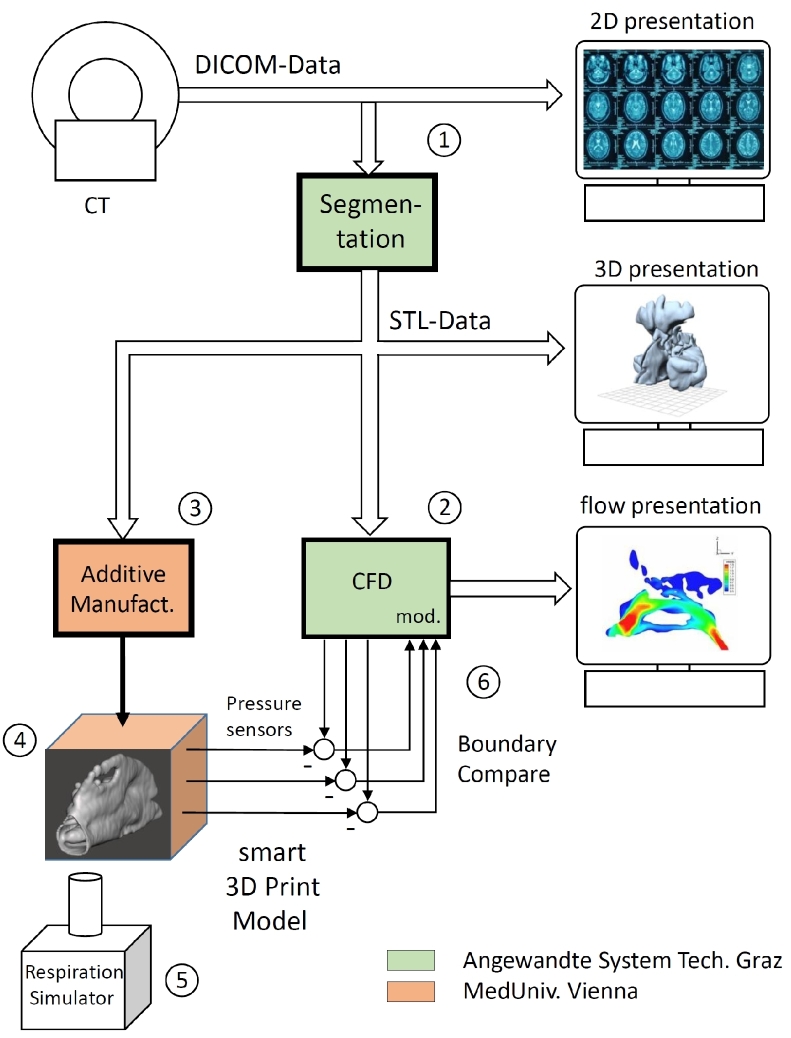

A Marching Cubes Algorithm is used to extract polygonal mesh from an input isosurface. Using this algorithm, one can generate 3D surface triangulations, from the 2D segmentations of air and bone. The algorithm is accurate and well suited for surface reconstruction. Application: CFD simulations; 3D-printing; fluid dynamics measurements with an artificial lung; classify and distinguish different anatomical structures (i.e. different sinuses, left and right). This work is done by AIT-Graz (Angewandte Informationstechnik ForschungsGmbH).

Smart additive manufacturing (Medical University of Vienna)

A polyjet 3D printer, which is able to combine 4 types of material with different Shore hardness is used to produce individual models for measurements in a testbed. To understand airflow (planning surgeries) and to validate CFD pressure sensors are adapted on defined positons on the 3 nasal air paths. Moreover the models will be used to introduce a training and learning setup for surgeons and students. During this project additionally we will perform material research for additive manufacturing to imitate soft tissue.

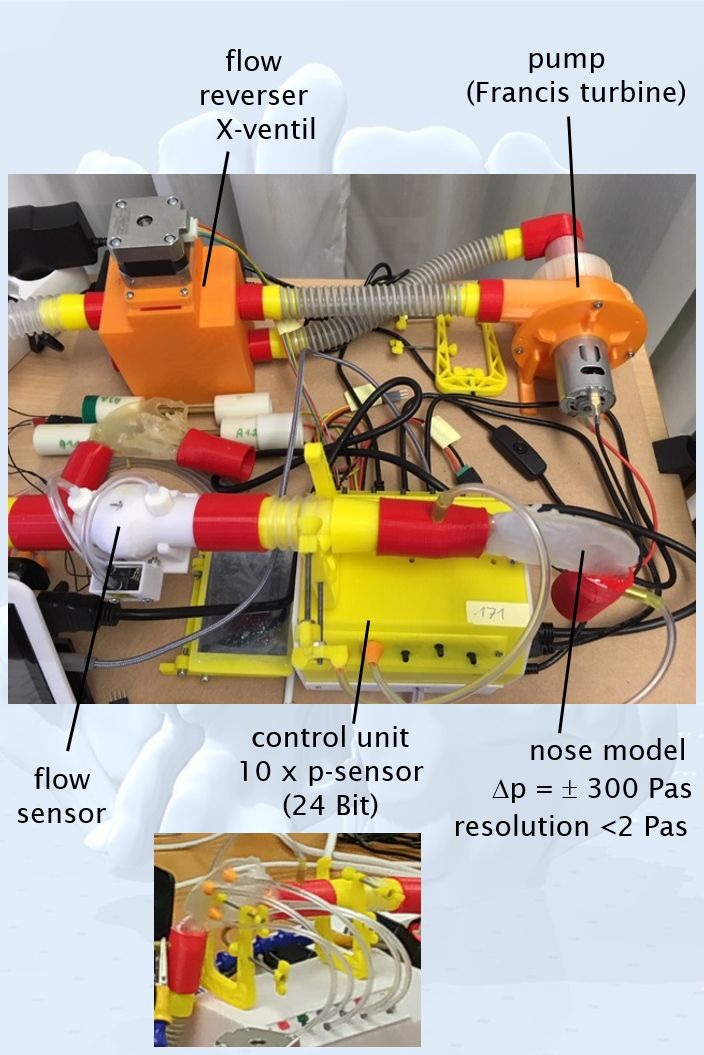

Testbed

A complete testbed includes high resolution pressure and flow sensors, transducer electronics, microprocessor and drives for motor and valves. For artificial breathing a rotational pump with a cross valve for in- and exspiration was built.

Using a rotational pump instead of a pistion pump in addition to natural breathing (periodical inhalation – exhalation) it is possible to produce constant airflow allowing to measure in a steady state modus.

The test bed – currently established at AIT-Graz will in future be used at MedUni Vienna for demonstration purposes for students.