The Center for Medical Physics and Biomedical Engineering has a number of technical facilities to support scientific work at the university.

In addition, the center offers a range of services, which are also available to non-university institutions.

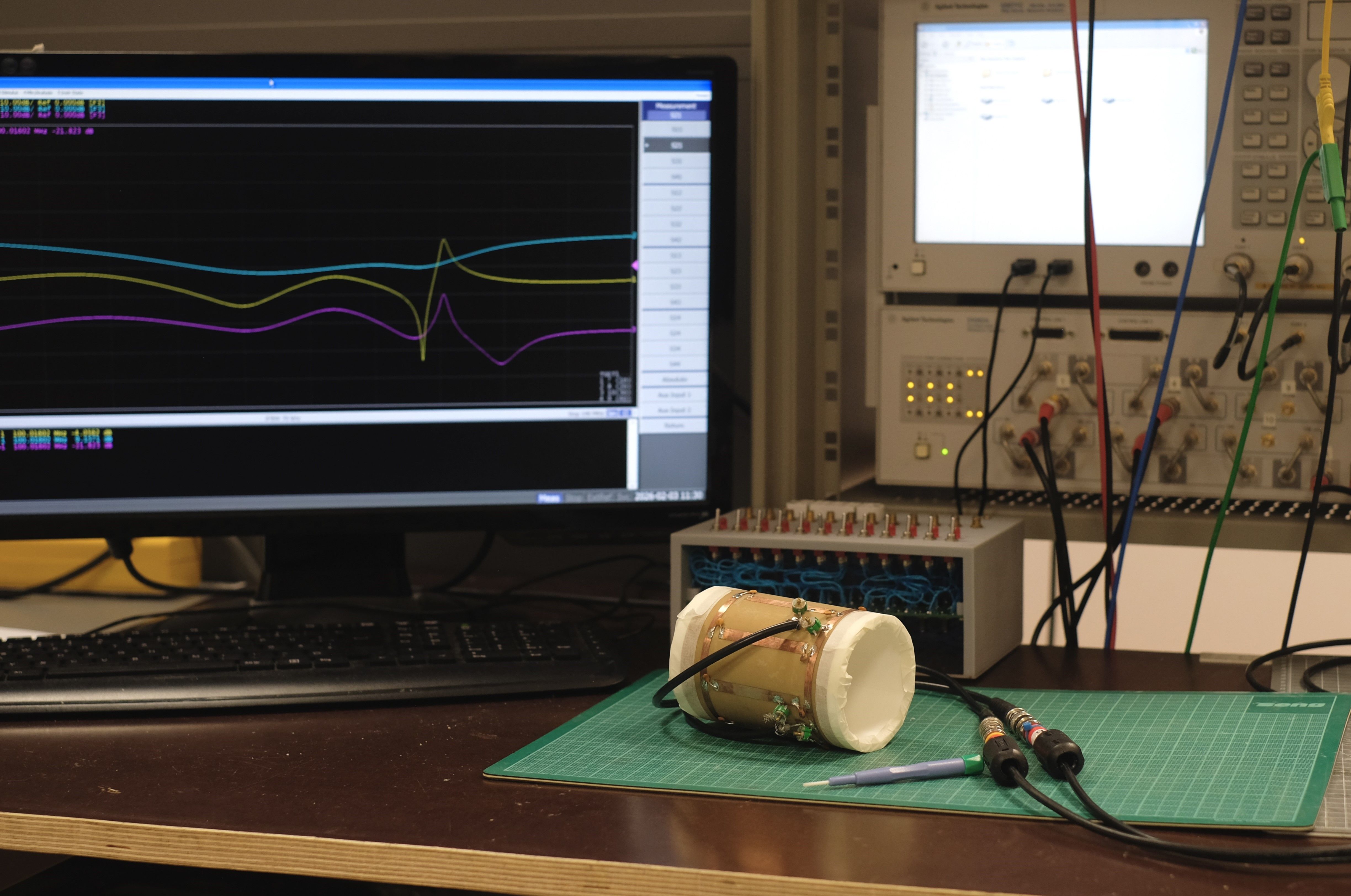

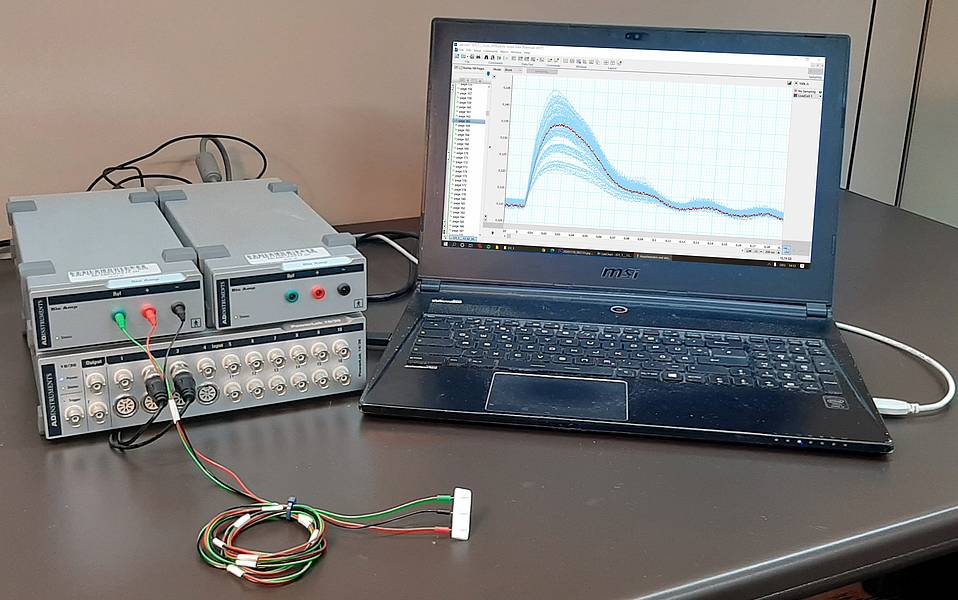

If terms such as sampling rate, bandwidth, signal-to-noise ratio, sensitivity and resolution cause confusion, shielding, grounding and earthing have to be taken into account in order to carry out a clean measurement, please feel free to contact us. We help you choose the right measuring device and advise you on setting up the test and measurement setup. We are also available with advice and action for developments for your research projects or experimental studies.

Hermann Lanmüller

P +43 (0)1 40400-39850

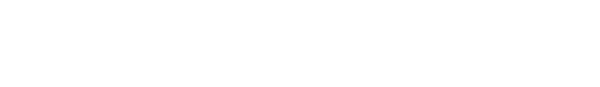

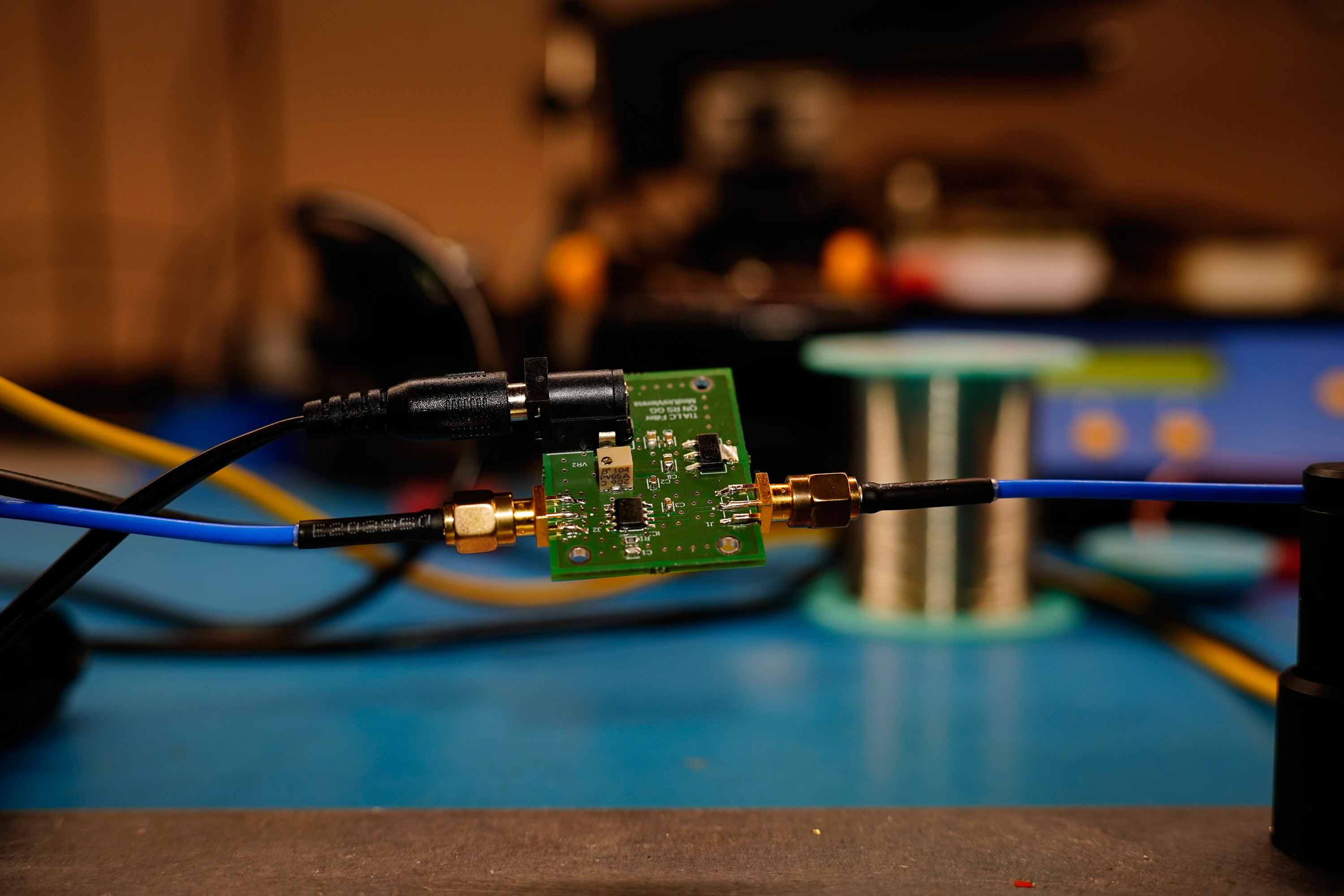

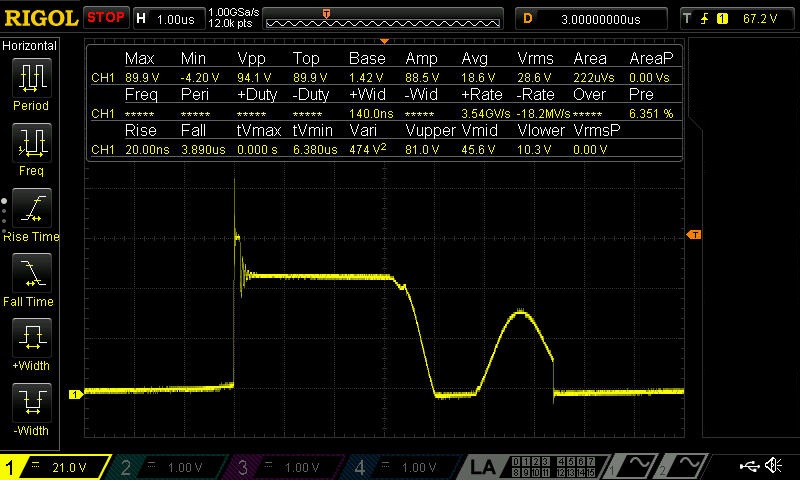

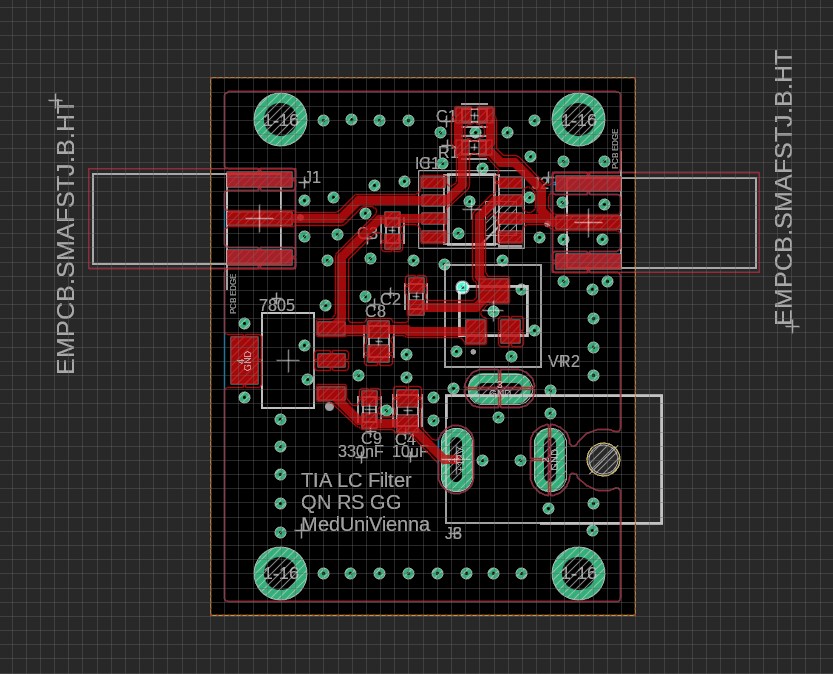

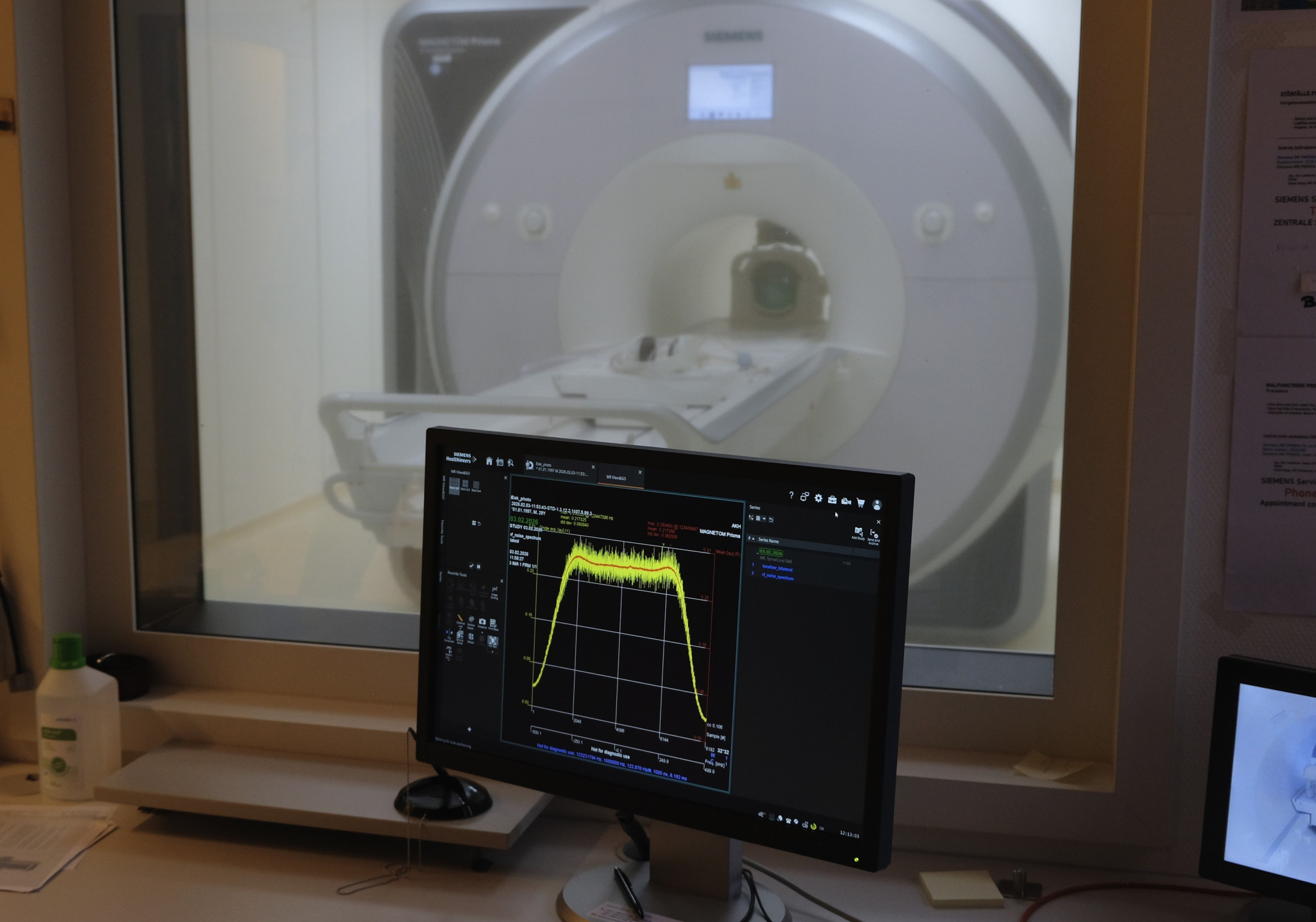

The Electronics Group supports the development process from the initial idea to the functional prototype. Circuit design, PCB layout, assembly and commissioning, RF technology and embedded software are among its core tasks. This expertise flows into the collaboration with the research groups in the centre's various research areas, biophotonics, magnetic resonance, conventional imaging and biomedical engineering, enabling work to be carried out to the highest scientific standards.

- Development of application-specific circuits

- Implementation of the developed circuits as printed circuit board (PCB) layouts

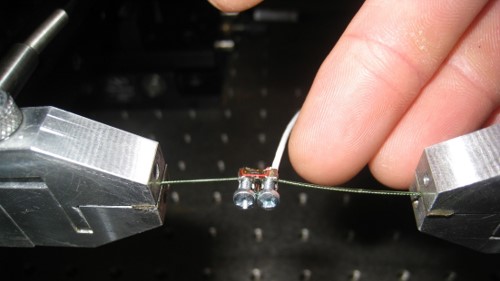

- Performing RF characterisation and MR safety testing

- Evaluation and optimisation of coil designs in terms of performance and safety

Quang Nguyen

Rostyslav Samonov

Onisim Soanca

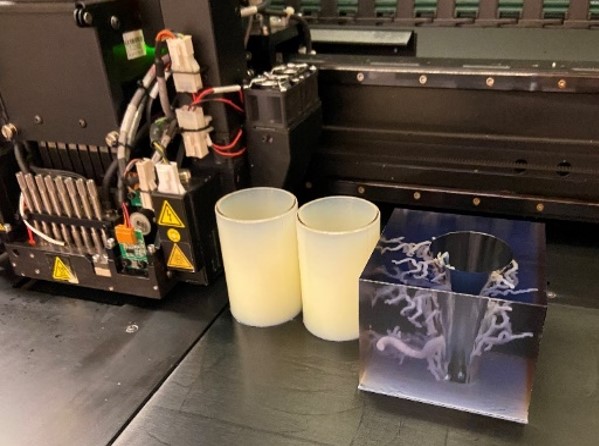

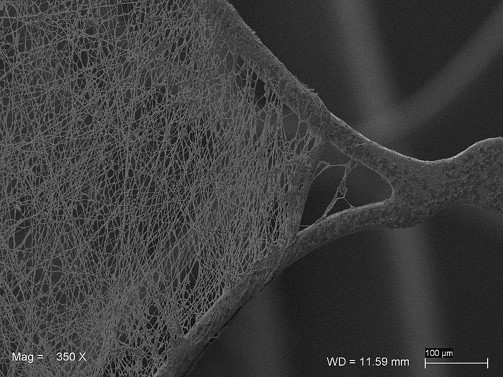

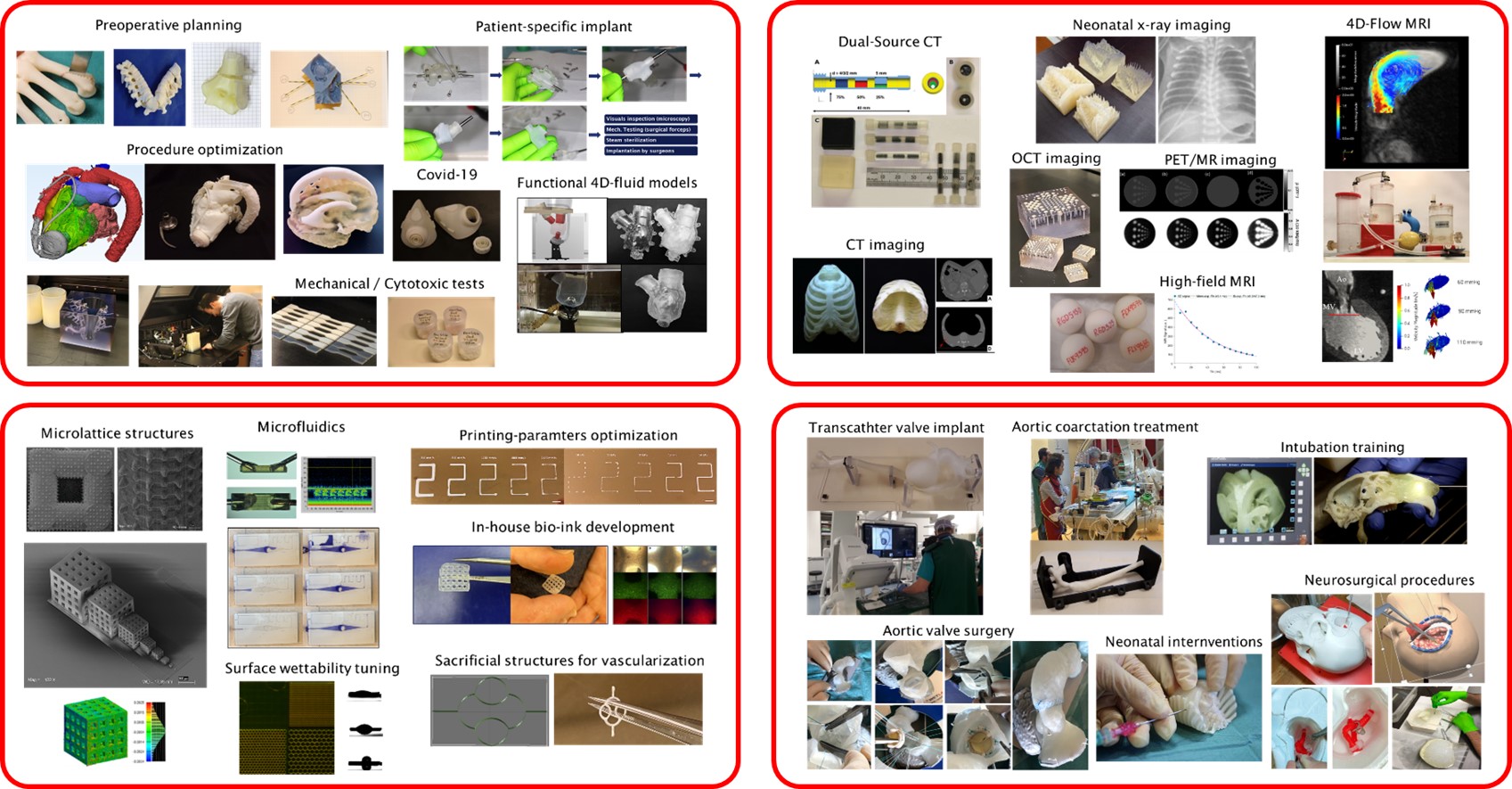

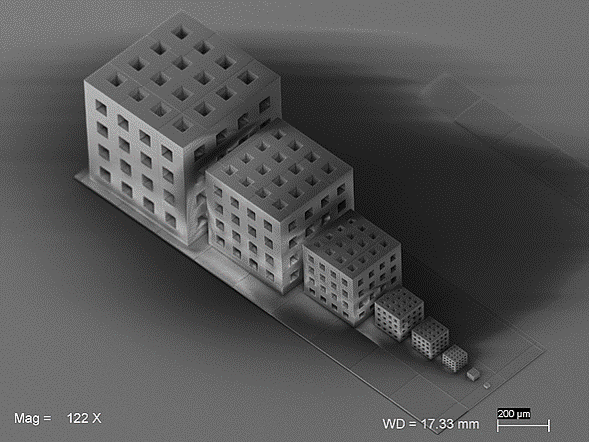

Our Center coordinates a large research infrastructure that provides access to several additive manufacturing methods and systems. Different materials ranging from (bio)polymers, metals and ceramics can be used. Parts in dimensions from mirco-nano scale to macroscopic scale can be manufactured. The devices have been installed primarily in our Center and also at the cooperating partner institutes including the Center for Biomedical Research of the Medical University of Vienna, PROFACTOR and ACMIT.

Francesco Moscato

P +43 (0)1 40400-39830

Ewald Unger

P +43 (0)1 40400-19890

Ewald Unger

P +43 (0)1 40400-19890

Gunpreet Oberoi

P +43 (0)1 40400-19890

3D Nano-Print

- Surface structures

- Phantoms

- Microchannels

minimal horizontal feature size ≥170 nm

minimal vertical feature size ≥550 nm

maximum part height 40mm

built size (x/y) maximum 20x20mm

Christian Grasl

P +43 (0)1 40400-61430

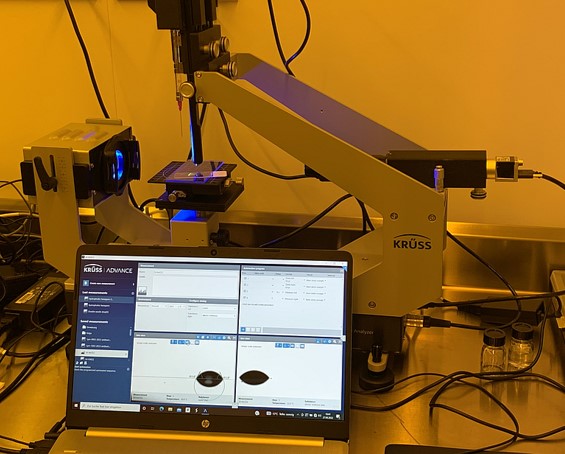

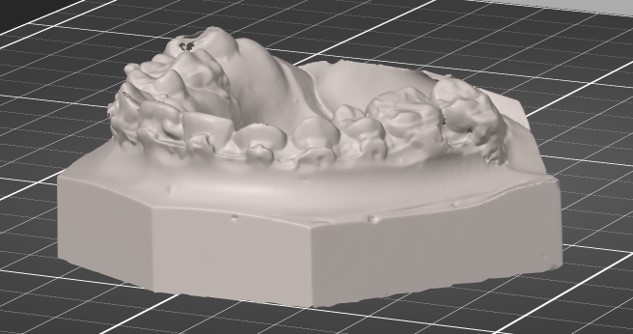

High resolution 3D Scanning

The scanner system offers a high level of detail and operates extremely stably and reliably even with temperature fluctuations. Within seconds, complex surfaces of fragile or deformable parts are captured with high precision. The scanner can also capture the texture of measured objects. A large measuring range and high resolution can be achieved through interchangeable lenses.

Martin Stoiber

P +43 (0)1 40400-61440

There are two different clean rooms at our centre.

Elektro-Mechanic Cleanroom

The cleanroom for electro/mechanical assembly supports different projects, which needs an assembly, moulding or electrical testing of implant, electrodes or delicate devices where an dust free area is needed.

Ewald Unger

P +43 (0)1 40400-19890

Polymer Cleanroom

This clean room (class 1000) is equipped with a laboratory oven, a clean workbench and an optical microscope.

Christian Grasl

P +43 (0)1 40400-61430

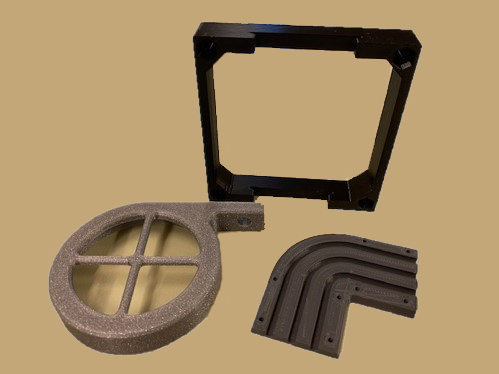

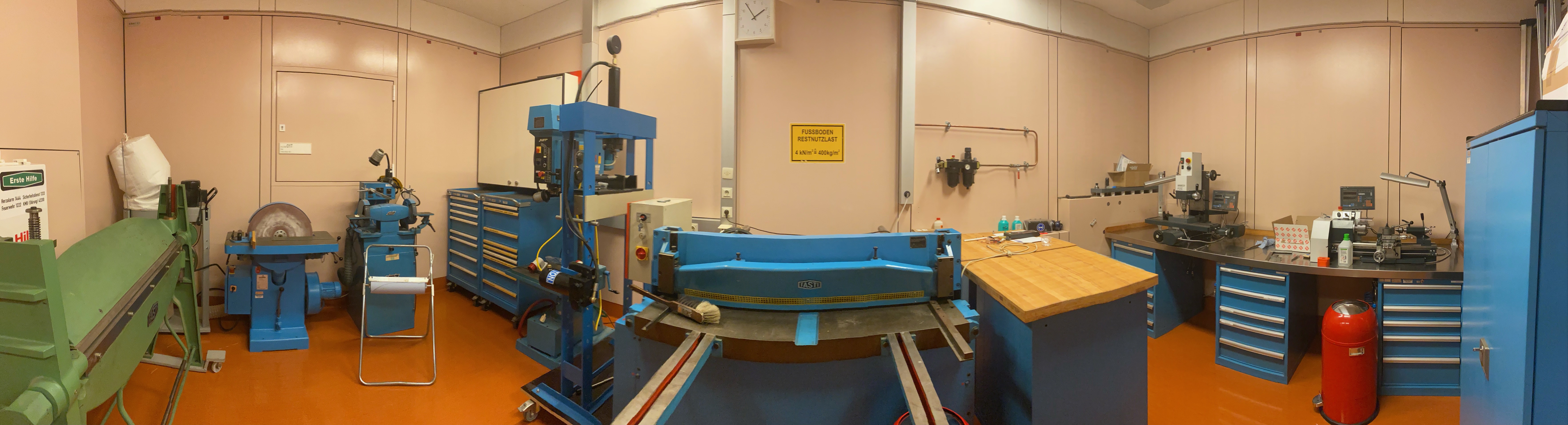

In our workshops, which are equipped with various lathes, milling machines and many other machines up to CAD/CAM software, we can process a wide range of materials (steel, plastics,...).

Our workshops offer the possibility to produce mechanical parts and devices from non iron material to steel. The team try to support you to realise your idea and to adopt your design on the different possibilities.

Contact: Andreas Hodul and Bernhard Rosenauer

Design and manufacturing of acrylic components

In addition to milling and turning, this parts are also glued and the surface treated here.

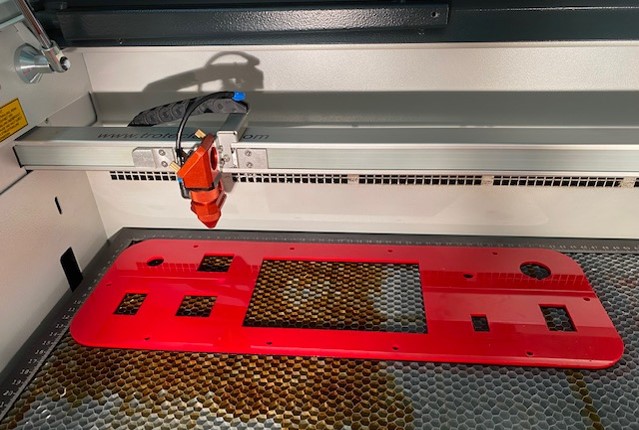

Laser cutting and engraving

Size: max. 720 x 450 mm

- Acrylic - Plexiglas®

- Wood

- Cork

- Leather

- Imitation leather

- Glass (engraving only)

- Selected plastics

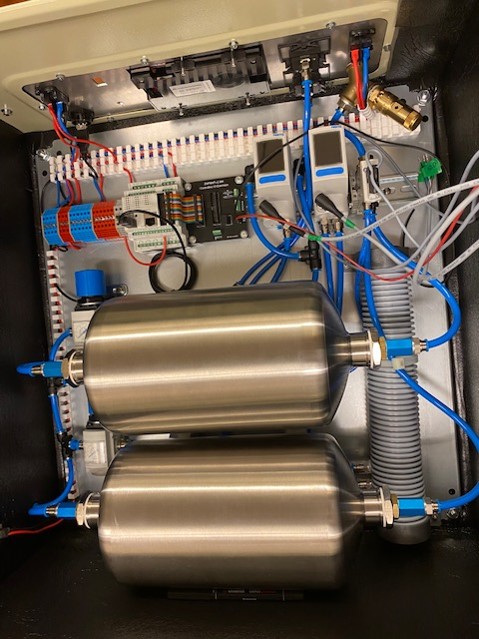

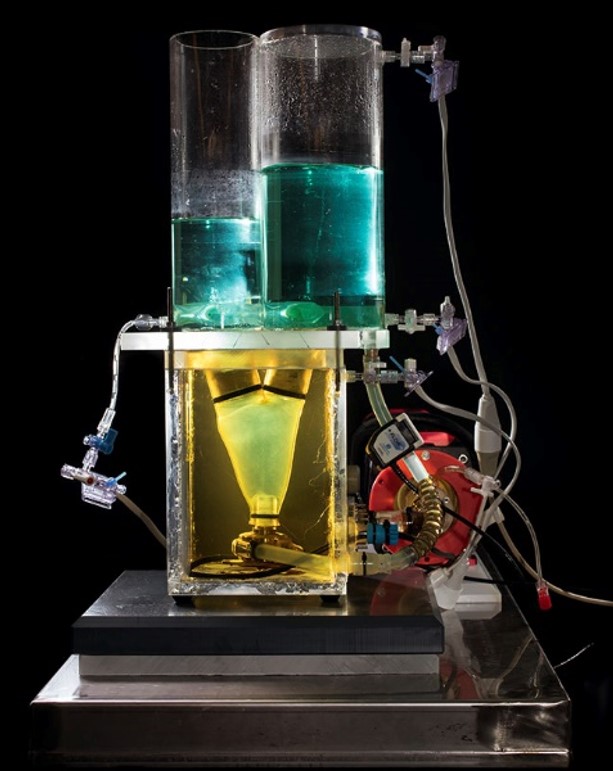

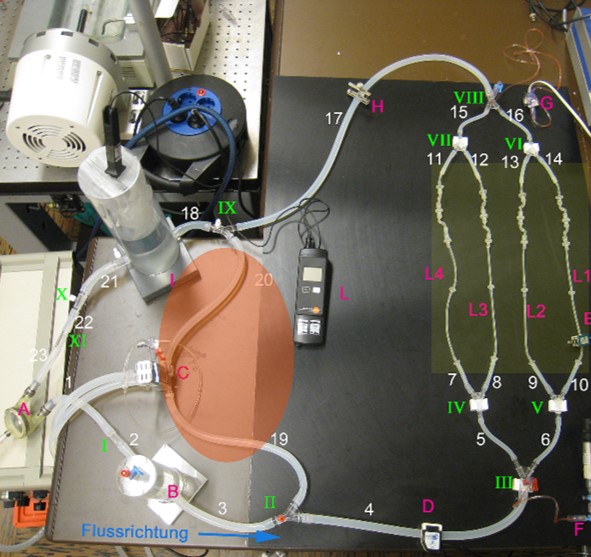

Hydraulic circuits

- Fluid circuits

- Pulsatile pressure and flow

- Simulation circuits

- Micro channel circuits

Casting of silicones and resins

- Design and production of moulds

- Hollow structures, transparent models or models with particles

- Bubble-free casting techniques

Martin Stoiber

P +43 (0)1 40400-61440

Christian Grasl

P +43 (0)1 40400-61430