Investigation of micro structures and devices and their interaction with biological tissue

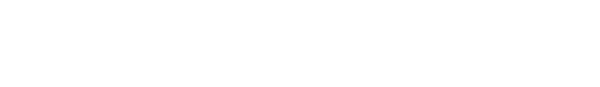

Ink-based hybrid multimaterial fabrication of next generation implants (INKplant)

This project aims at the development of a hybrid additive manufacturing process, which provides advanced multi-material subperiosteally implants personalized to the patient. In particular, our efforts are devoted to the design of 3D-printable cellular meta-materials, which mimic the heterogeneous nature of human tissues, and their computational and experimental evaluation. Focus is laid on the implant biomechanics and on the mechanobiology of cells interacting with the implant. This project has been funded by the Austrian Research Promotion Agency (FFG).

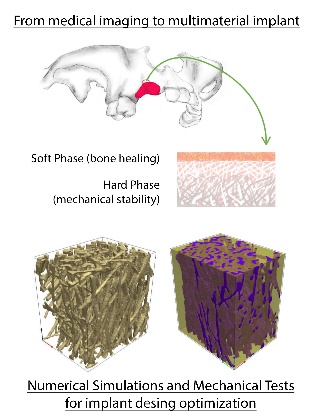

Micro- and nanofabrication

Two-photon polymerization stands out as a powerful method for the tailored fabrication of complex microstructures with a high resolution. The technology is very complex but essential for manufacturing bioinspired applications like antibacterial surfaces, various imaging phantoms (MR, OCT), and microcircuits for microfluidics. Additionally, geometrical, mechanical and biocompatiblity tests of the printed nano-/microstructures are performed.

Material and structure interaction with cells

The advancing clinical application of additive manufacturing technology greatly relies on the availability of biocompatible printing materials. Therefore, 3D printed materials are tested for toxic effects on clinically relevant cells in vitro prior a possible clinical translation. We perform in collaboration with preclinical and clinical institutes of the Medical University of Vienna standardized tests to evaluate cytotoxicity of 3D printing materials based on the ISO 10993-5:2009. Furthermore, the influence of surface microstructures and patterns on cell viability are investigated.