Detailed KnowHow and Various Technologies for development of blood pumps and components

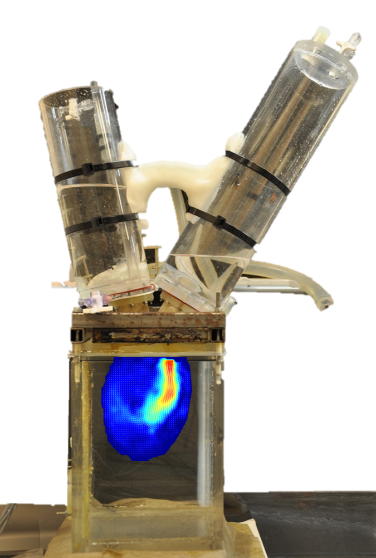

Hydrodynamical Simulators for developments and diagnostics

For the evaluation of assist devices, prosthesis and diagnostic tools in-vitro tests are indespensable. Such simulations require the mimicing of very different hydraulic conditions in the heart itself, in the pulsatile aorta and arteries, in the venous system and in pumps. Depending on the particular problem, the test fluid have to mimic hydraulic properties, ultrasonic echo properties similarly to blood, optical reflectivity for flow visualization and particle image velocimetry or sterility and special metabolic properties for cell cultures. Over the years, our group has developed a whole battery of test pumps, mock circulations, and hybrid circuits to fulfil all the different requirements.

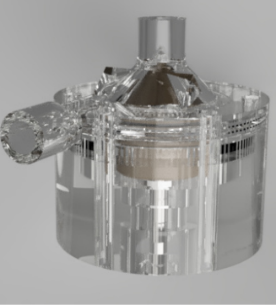

Inflow cannula for a minimally invasive Ventricular Assist Device

An inflow cannula was developed with a specially shaped tip for the use in transatrial access to the ventricular cavity. The cannula tip was optimized by the use of Computational Fluid Dynamics (CFD), to allow suction-free uptake of the blood from the ventricular cavity. Three large lateral inflow orifices and a special tip shape provide stagnation-free inflow. The crucial part of the tip is a cone shaped structure in the middle, this avoids undercuts in the flow area, which normally exist at lateral orifices. A patent for this design has been registered.